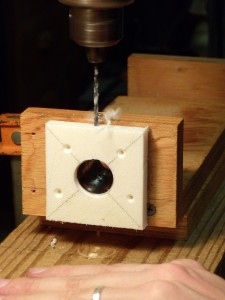

I manufactured a second copy of my bracket and used my hand drill to put a few holes in them to hold bearings. The idea is to mount 3 inline skate bearings at 120 degree increments around a pipe to limit motion to 1D (two of these on one side, plus two 2D mounts on the other side, make a Z-axis platform). I estimated the space taken up by the washers, and got it wrong, so if I wanted to use this design I will have to tweak my design and make a few “off-size” brackets to pair with the current ones I have. (Making all new brackets does not sound like fun, as each of them take almost 2 hours of routing time). The alignment and motion is a bit rough (I did eye-ball the holes) but I think I could improve upon that enough to make them passable with enough practice. However, due to the two-hour build time, I’m seriously considering using the “standard” angle-iron solution for my Z-axis.

I harvested the bearings you see (and all the hardware that isn’t wood) from a pair of in-line skates I purchased at a Goodwill store for one dollar. They are ABEC-3 bearings (which are not as good as ABEC-7) but for $1 I got 12 bearings (2 per wheel, the skates had 3 of the 4 original wheels), hex bolts and associated plastic sleeves. They are standard skate bearings (8mm ID, 22mm OD, 7mm width) but much cheaper when obtained used.

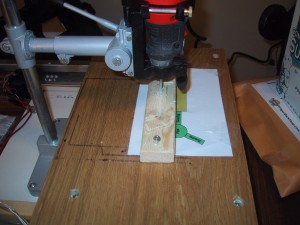

Below are a few photos and a 4xSpeed video of the manufacture of my 2nd bracket (which doesn’t have as much burnt wood, and no problem areas):

Pingback: Jay’s Technical Talk › Angle-Iron bearings and Z-axis