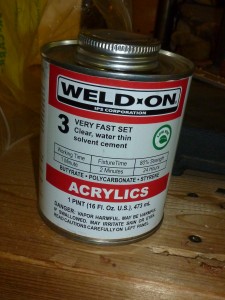

I finished test column #1 today. I was able to cut the extruded acrylic tube using a miter saw with no major difficulties, and pulled it across a piece of sandpaper on a glass backing to try to ensure that the end was perfectly flat. I had to use a good amount of solvent to weld the 1″ square bottom plate to the bottom of the square extruded acrylic tube. Even after my initial weld, it had some pinhole leaks that would “weep” water. I fixed them by turning the tube sideways and wiping a liberal amount of solvent along each of the four seams, allowing it to seep into the gaps (and/or melt acrylic into the gaps.)

As far as I can tell from watching it, the column has no leaks. I marked the water level using a rubber band, sealed the top to prevent evaporation, and will check it over time to see how the bottom of the column is holding up. Of course, I’ll have to repeat my test with a full six foot column (due to the extra pressure) but so far it appears the acrylic bottom plate welded onto the tube is going to work well.