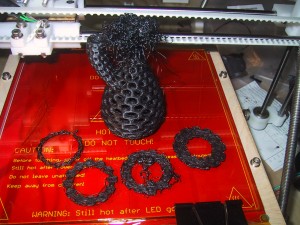

After building a few utilitarian objects I decided to really push the envelope of what my 3D printer could do. I wanted to build the Klein Bottle model by Dizingof as soon as I first saw it because it’s so cool looking.

In addition, it makes a great test print because it’s a very large STL file (23MB!) which takes forever to slice (84 minutes!) and produces a 14MB gcode script that takes a long time to even load and display in Pronterface. If you can slice and print this model, you can slice and print anything!

From a topography standpoint, it is challenging for a 3D printer for several reasons.

- The area that touches the base plate is very small (unless you add a raft of material under it) so if you don’t have good adhesion of your first layer, the whole model may lift up and slide around.

- It has lots of vertical holes that need to be bridged. Without a dual extruder system that uses support material, your printer needs to make use of gently increasing overhangs and sometimes just stretching strings of ABS from one side of the gap to the other.

- Finally, it’s a tall thin model. Not quite as bad as the Empire State Building, but if you have excessive vibration you may find that the top of your print is jumping all over the place. Plus, at 102mm, it’s actually a few mm higher than the rated size of my Prusa Mendel’s build envelope. I made it work by taping straws over my frame rods so that the X-axis belt could slide over them without damage as it got to the very top and pushed beyond.

I have the overview movie stitched together from videos here:

And a video of the full 1 minute per frame timelapse here:

Of course, it didn’t work perfectly the first time….I had to start the Klein Bottle print about four times before I figured out the trick to get it to stick to the build plate. The trick was to zero my nozzle about a layer UNDER the build plate surface. (So that it was scraping the build plate…) Then, when starting the print, I manually held the build plate down about one layer thickness (just press down hard against the springs) as the very first layer of the klein bottle print is really very small (just the tips of the touchdown points) and then let the 2nd layer act as the “true” first layer. The second layer has a lot more surface area and sticks much better. Even then, if you have a bug in your gcode that lets the build plate cool down to 60 Centigrade instead of staying at 110, the print may eventually break off and start sliding around after several hours while you are not watching it and POOF, Carrot Top!