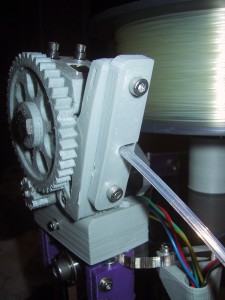

This is my new extruder hot end. After enclosing my printer with an insulated box, I decided that I needed to drop more heat before the plastic entry side of the end of the barrel. I accomplished this by turning an extra long barrel out of brass, and a small heatsink out of aluminum to go between the heater and the Groove Mount.

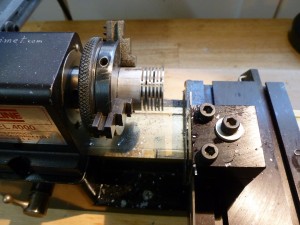

You can see the barrel compared to the original part here:

The barrel was straightforward to turn out of a piece of 1/4″ hex stock. I put the threads on with a metric M6x1 die.

The HeatSink took more time, mostly because I had to cut the fins out of a 1″ diameter rod quite deeply with a cut-off tool.

I compressed the several hours of work on the heatsink down into a six minute video below: