My Chevy S-10 electric truck is about to get a new charger, and the upgrade will also include a new set of charging inlets hiding behind this J1772 novelty front license plate.

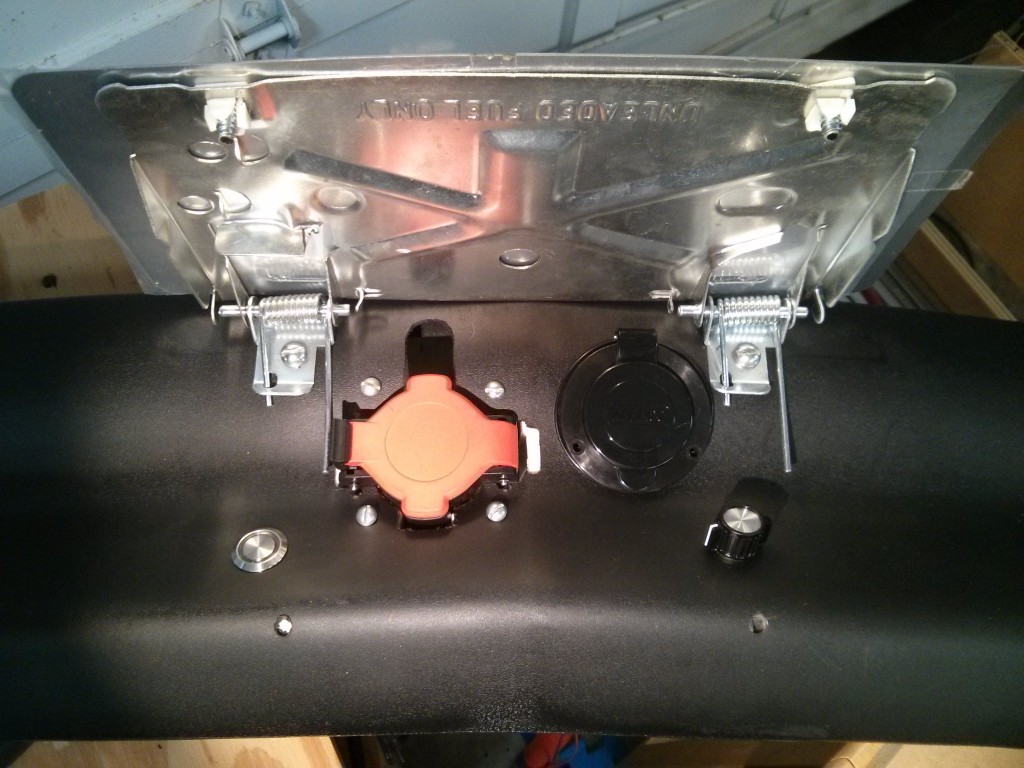

When you flip the license plate up, it reveals a J1772 inlet, as well as a 15 amp 120 volt RV inlet that any standard extension cord can plug into. I also have a rotary switch to select different charging modes, and a push button with LED indicator light to enable the charger and flash status messages.

Here is a video overview of the setup:

YouTube Video

To prevent both inlets from being energized at the same time, I will be routing them through a power relay to the charger. The J1772 inlet will be connected by default. This will make sure that the exposed plugs on the 120 volt inlet are never energized by the 240 volt J1772 source.

If 120 VAC is present on the 15 amp RV inlet, the relay will connect it to the charger (and disconnect the J1772 inlet). I’m not terribly worried about people reaching into the J1772 inlet, as the plugs there are designed to be finger safe, but I don’t want some idiot plugging the J1772 inlet AND an extension cord into the truck at the same time and accidentally connecting 240 volts to a 120 volt circuit.

The rotary switch will allow me to switch between four modes on my charger.

- 12 amp opportunity charging (from the 15amp RV inlet). This will support charging at any 120 volt 15 amp outlet with a standard extension cord. An extension cord is easier to carry around than a full 120 volt EVSE adapter, and costs a lot less to replace if somebody steals it.

- A low current equalization charge mode, used very rarely to top balance the pack.

- An 80% battery charge, to maximize battery life (this will be the mode used for most charges at home).

- A 100% battery charge, to maximize range (if needed) or to get the pack ready for the low current equalization charge.

I plan on also having a small 120 volt switching relay that will automatically put the charger into mode 1 (12 amp draw) if it detects 120 volts on the RV inlet, so that anybody can plug an extension cord into the truck, push the button to charge and have it “just work”.

Physical Mounting

Once I had the front air dam to mount everything to, it was just a matter of work to cut out all of the appropriate holes and bolt things on. The J1772 inlet was the most finicky as it had the only non-round mounting hole. I used a 2″ hole saw for the main circle, and then a rotary tool with small cut-off blades and a grinder to shape the “cross” arms. I also cut down a piece of high density foam with a hole saw and razer knife to match the contour of the air dam and recess the inlet appropriately behind it.

The flip up license plate adapter came with very strong springs that hold it in place, but I was worried that they would put too much stress on the J1772 gun (potentially pushing the disconnect button) and they also made it difficult to just lift the plate up, even when using a spring on only one of the two hinges. I eventually mounted the hinges such that the springs were not engaged and am using magnets to keep the plate from rattling around while I drive.

I ground down the tips of the mounting screws, added holes in the air dam at the appropriate places, and glued rare earth magnets behind it. When the license plate is pushed down, the screws touch the magnets and latch quite firmly. It takes a good tug to detach the screws from the magnets, but once you do, the plate flips up very easily.

Update: Here is what it looks like being used on the truck:

Pingback: New charging inlet & Drive Away Protection | Jay's Technical Talk