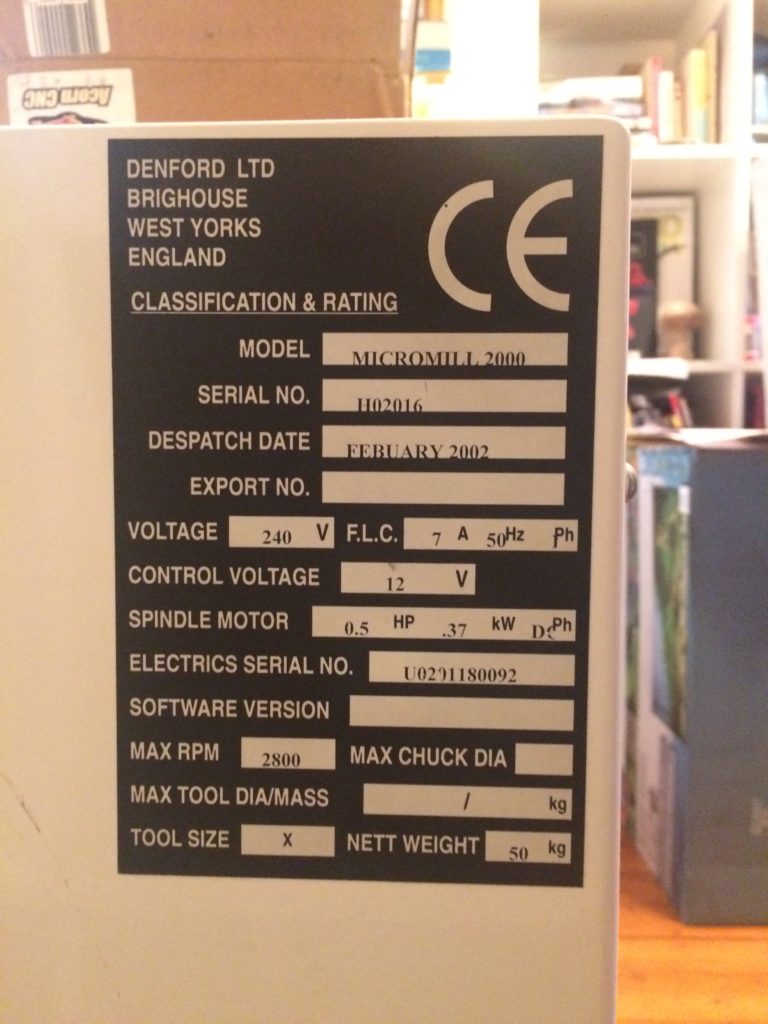

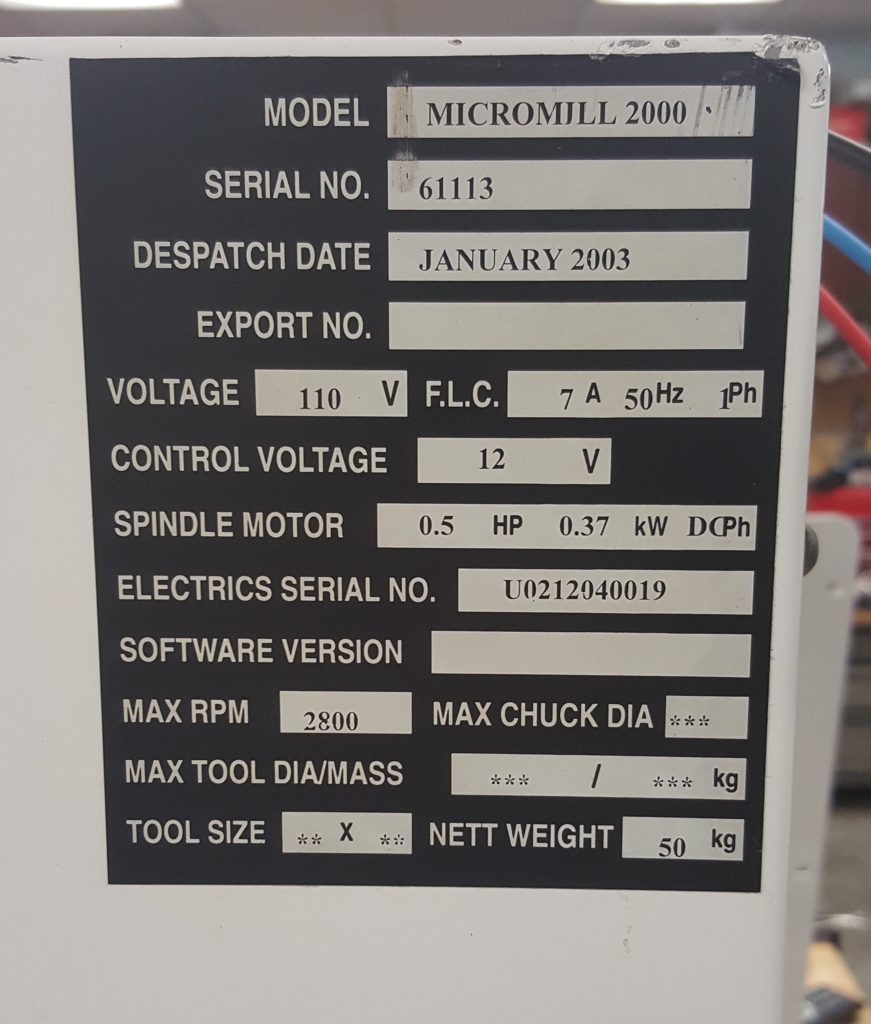

When I purchased the ScanTek 2000 Scan Mill (A rebranded Denford Micromill) from a surplus supply house, the spindle motor was at an odd angle and the drive belt had frayed (probably due to the angle).

When I purchased the ScanTek 2000 Scan Mill (A rebranded Denford Micromill) from a surplus supply house, the spindle motor was at an odd angle and the drive belt had frayed (probably due to the angle).

When I took the motor off, it was clear that the problem was a bent bracket.

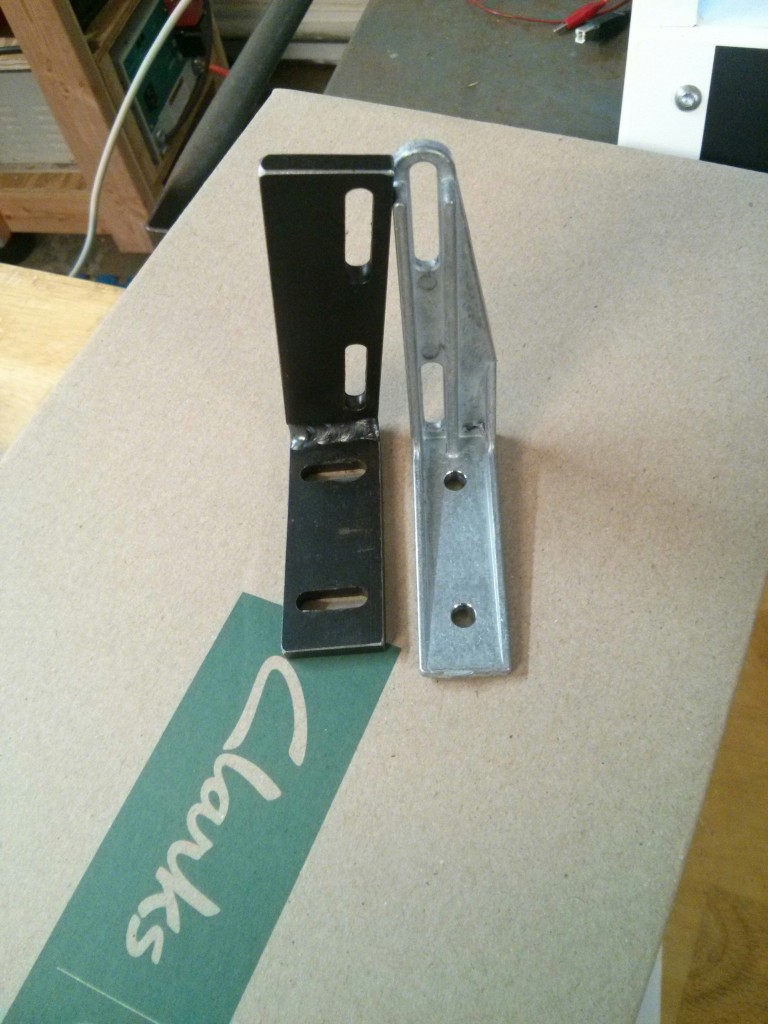

Since I needed to purchase a new drive belt ( Sherline PN 40040 – $9) I decided to just buy a new Sherline spindle motor support bracket (PN 40020 – $7 ) at the same time because it was relatively inexpensive.

When the new bracket arrived, it was not quite the same.

First, it had some nice reinforcing ridges cast in that make it look a lot less likely to bend than the bracket that came with my ScanTek. However, it is a straight 90 degree bracket, while the ScanTek bracket has a slight 5 degree cant which locates the spindle motor about a half inch farther back into the steel enclosure. Although the Sherline bracket mounted the spindle motor just fine, it was pushed forward a half inch from the original location, which meant that I couldn’t move the Z-axis all the way up because the spindle motor would hit the top of the case before the home switch activated.

My guess is that Denford manufactured these special brackets so that the spindle motor would fit inside their steel case, and that is why they are not quite as mechanically sound as the Sherline standard brackets. (Or, it is possible that Sherline has just improved their brackets over time, since I did buy a 2016 version and was comparing it to a 2004-2005 version.)

Since the Sherline bracket wouldn’t work without repositioning my home switch and losing an inch of travel on the Z-axis, I decided to repair the original bracket after all. With a vise and my bare hands I was able to bend it back to 90 degrees. This was good in that it was now square, but bad in that the bracket was weak enough that I could bend it with my bare hands and no cheater bar. (This is probably why the bracket was bent down to begin with.)

I grabbed some spare steel I had laying around, cut it to size, cleaned the welding points up a little, and welded it on to support the 90 degree bracket. Then I painted it black to disguise my ugly welds and protect it from moisture in the air.

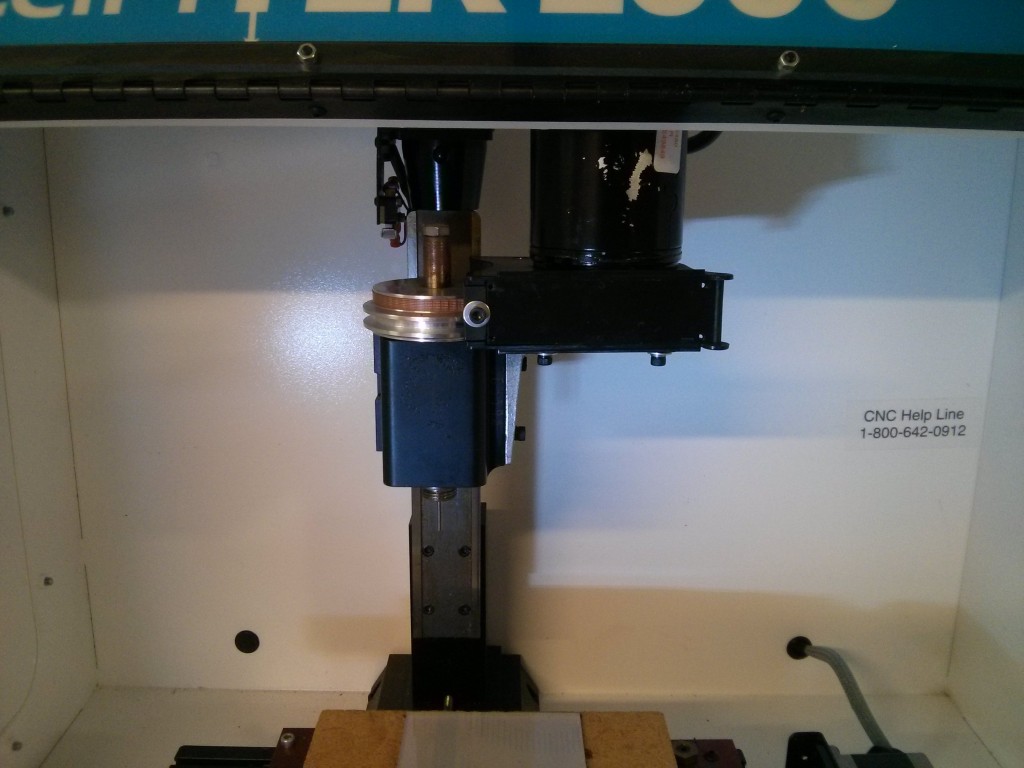

And here is the final product mounted on the Mill (A bit more than $7 worth of work…):