The FunCreCol 102 “tough” (gray) resin produces prints with good resolution that have a little flexibility. They are not “flexible” like TPU, but do have a little “flex” and will generally bend instead of breaking. It is MUCH less brittle than the FunCreCol standard (101 – white) resin (But also costs more, and takes a bit longer to print due to the longer exposure times required).

The only issue posed by the flexibility is when using light/thin supports with certain geometries, it is possible for the support structure or small parts of the print to flex and not fully pull off of the film, which can sometimes lead to distortions or “bad spots” in the print, typically focused near the small islands or near the beginning of the print. You can resolve these issues by using larger (medium/thick) supports or carefully positioning your prints to avoid small areas that would be susceptible to flexing while being pulled off of the film.

Also, you may need to work harder when removing supports, as the support structure tends to “flex” instead of snapping off the part cleanly. If you have a small delicate part similar in size to the support material, you need to manually break the support material off one point at a time before yanking the support material away (or risk the support material also flexing/breaking your part when you yank it away).

On the plus side, if you have support trees going up inside of a print, after you break off the tips, it is possible to pull a large “tree” out through a small hole as the support is very flexible and the “tree” structure will flex through a hole smaller than itself.

I found the print quality to be as good as any other resin (on my bottom of the line Phrozen Sonic Mini printer), the parts were very strong with a small amount of flexibility. If you bend them a little they just spring back to shape. If you bend them a lot, they may remain slightly bent. And I had to really abuse them (folding things completely in half with a tight radius) to get them to snap in two.

The resin is not as “sticky” as others I’ve worked with, but it does not flow off of the build vat and build plate as nicely as the FunCreCol standard (101) resin does, so you may need to squeegee or wipe excess resin off of your printer before throwing the parts into your washing station.

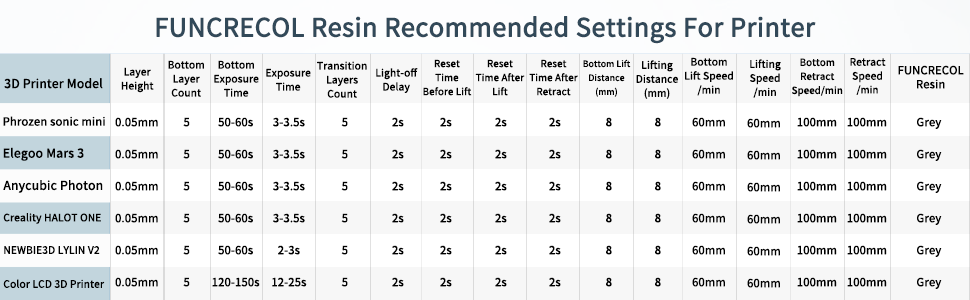

I used all of the settings suggested for my printer that came from FunCreCol with the exception that I increased the exposure time for layers by 1 second and the base layers by 20 seconds. [I have found that my printer needs an extra second for most resins, possible as it is getting old, or perhaps due to the cooler temperatures in my garage.]

At the current $34 price point, I feel it is a good deal for a “technical” resin. [At the original $42 price point, it cost about the same as other “tough” resins from name brands that might match your printer.]

Here is an archived image of their recommended settings for various printers:

You can also watch my video review of the Funcrecol Standard 101 white resin here.

Pingback: Review: FunCreCol Standard White 101 photo-polymer resin for DLP/LCD 3D printing | Jay's Technical Talk