My truck’s charge controller supports the J1772 protocol, and I have added a J1772 inlet I took out of the same salvage Nissan leaf that provided my LiIon battery pack.

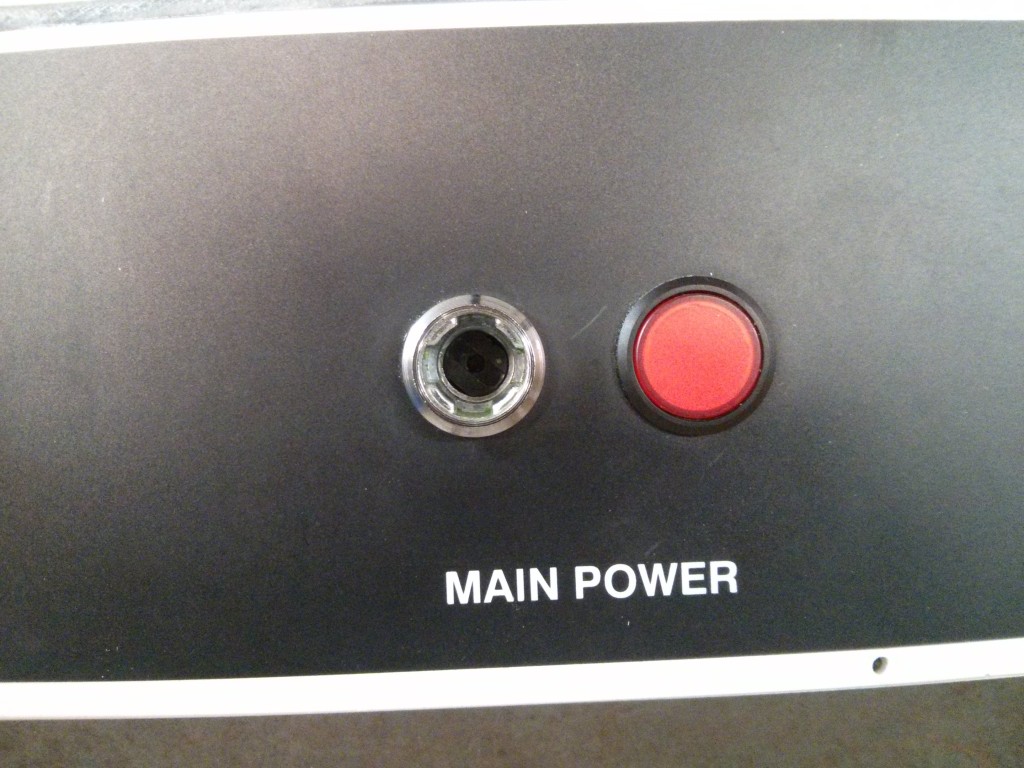

I added the J1772 port, the “start charging” button, and a rotary switch to select between different charging profiles, as well as a 120 volt, 15 Amp RV inlet behind a flip up license plate.

When you have one charging inlet, things are simple and safe. When you have more than one, things can get complicated. In my case, I wanted to use the same charger(s) with both inlets. But I shouldn’t just wire them both up in parallel, because that would mean that the (male pins on the) RV inlet would be energized at 240 volts when charging via the J1772 plug, and it wouldn’t be good for somebody to reach in and touch them. Also, if somebody were to try and plug in the J1772 AND a 120 volt extension cable at the same time, they would be connecting a HOT (from the J1772) line directly to the Neutral line on the 120 volts (causing a short circuit). [Having the J1772 inlet energized with 120 volts is also undesirable, although slightly less dangerous, as the J1772 inlet is designed to be “finger safe”.]

Continue reading →

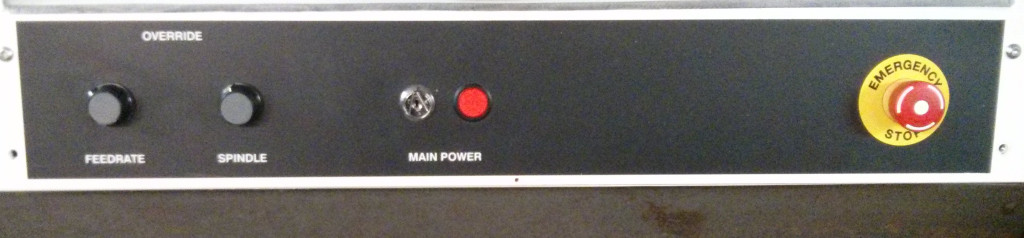

When I purchased the ScanTek 2000 Scan Mill (A rebranded Denford Micromill) from a surplus supply house, the spindle motor was at an odd angle and the drive belt had frayed (probably due to the angle).

When I purchased the ScanTek 2000 Scan Mill (A rebranded Denford Micromill) from a surplus supply house, the spindle motor was at an odd angle and the drive belt had frayed (probably due to the angle).