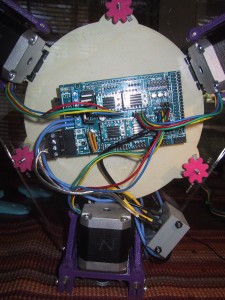

Now that my Rostock-Mini is basically finished, I have been adjusting the parameters of Slic3r to increase the print speed. Why? Because this is my sports car 3D printer….It’s small, looks cool, and is fast! In contrast, my Prussa Mendel is the family mini-van: Nothing to look at, reliable, with a large print volume.

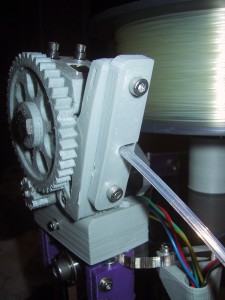

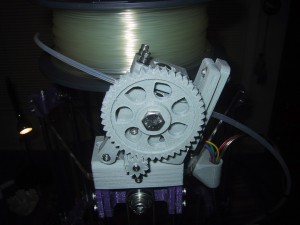

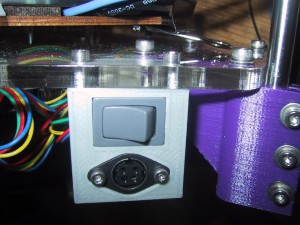

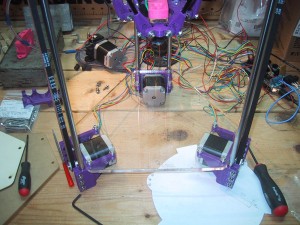

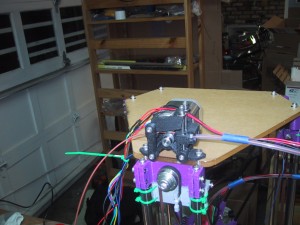

Because the Rostock-Mini has the cold end of my extruder mounted on top of the frame (not on the motion platform) it doesn’t have to move the weight of the extruder stepper, gears and associated hardware. The filament is pushed down to the platform via a bowden tube (think bicycle brake cable) and the only part that needs to accelerate and decelerate is the hot-end and associated fan / air duct. The lighter the platform is, the faster it can move and change direction while maintaining positional accuracy.

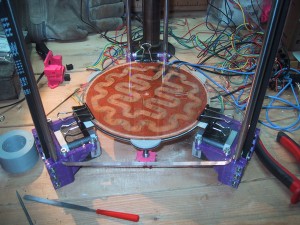

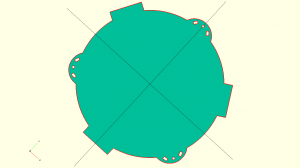

The Twisted Kochflake vase that I’ve been using for my test print has 7 layers at the bottom with “infill” but above that, it’s just made up of four perimeters of plastic traced around the volume of the interior of the vase. This means that some layers require a relatively short amount of motion/time, especially near the lower part of the vase. I have my Slic3r software set up to not allow any layer to take less than 15 seconds to give the plastic a bit of time to solidify before we put the next layer on top of it, so in some parts of the videos below the platform is not moving at it’s true top speed because of this software limitation. Also, due to acceleration constraints, the platform can’t get up to full speed on small bumpy surfaces. When the printer is printing the bottom seven layers (you’ll see it going back and forth to fill in the circle with plastic) or the wider part of the fractal pattern as the vase grows up you’ll see where layers take longer than 15 seconds (4 times around the vase is a single layer) and the platform will be moving at top speed.

Here is my printer set to 225 mm/sec, which is faster than most printers that have a moving single extruder will be able to do:

Here is the twisted Koch Vase at 150 mm/sec, which is approaching the top speed of most gantry style homebrew 3D printers that move the cold end of the extruder.

This is a relatively slow 75 mm/second video: