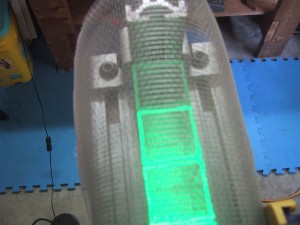

Here is a video of 22 tubes running with water:

Now for the bad news….22 tubes actually measure 22 1/8″ wide. (apparently each tube is actually 0.00568 inches larger than 1″) This means my entire display would be 3/8″ too narrow, which just won’t work with the tolerances I have designed into my tube holder. That is why I only have 22 tubes in this video….the 23rd tube was just far enough off to not fit into it’s proper hole.

I fixed it by cutting the tube holder into 3 pieces and mounting them with a 1/4″ gaps between them.

I also had to space the end pieces of aluminum farther out, which meant I had to drill 4 new holes to mount the side brackets to the bottom board 1/2″ farther apart. Luckily the T-Sloted aluminum mounting system allowed me to easily move my L-Brackets up slightly to hit the new holes.

Unfortunately, I mounted the Shift MOSFET circuit boards on TOP of the screw heads holding the tube support board, so I had to take them all off to re-position the tube support board. Annoying, but not the end of the world.

So, after a bit of additional work, I now have all 60 tubes working.