I need optical magnification to work on small crafting projects. However, I also wear prescription lenses, so used a headband based magnifier that I could wear with my glasses. It worked fine, but I didn’t like having to wear two different things on my head, and the forehead mount was a little uncomfortable.

So, I’ve come up with a trick that allows you to order prescription glasses that include a magnifying inset lens. For those of you who wear bifocals…yes, I’m talking about bifocals. By turning the NV (Near Vision) field of a bifocal prescription as high as you can get it, you can get a magnifying bifocal insert of 1.87 X or greater.

The formula that relates optical magnification to dipolars is:

Magnification = (Dipolar / 4) + 1

So with the maximum +3.5 dipolar Near Vision (NV) setting allowed by Zenni Optical, I’m able to get prescription glasses that include a 1.87X magnification inset.

Of course, they are down near the bottom of the field of vision, which works OK for reading in your lap, but not as great if you paint with your elbows on the table like I do.

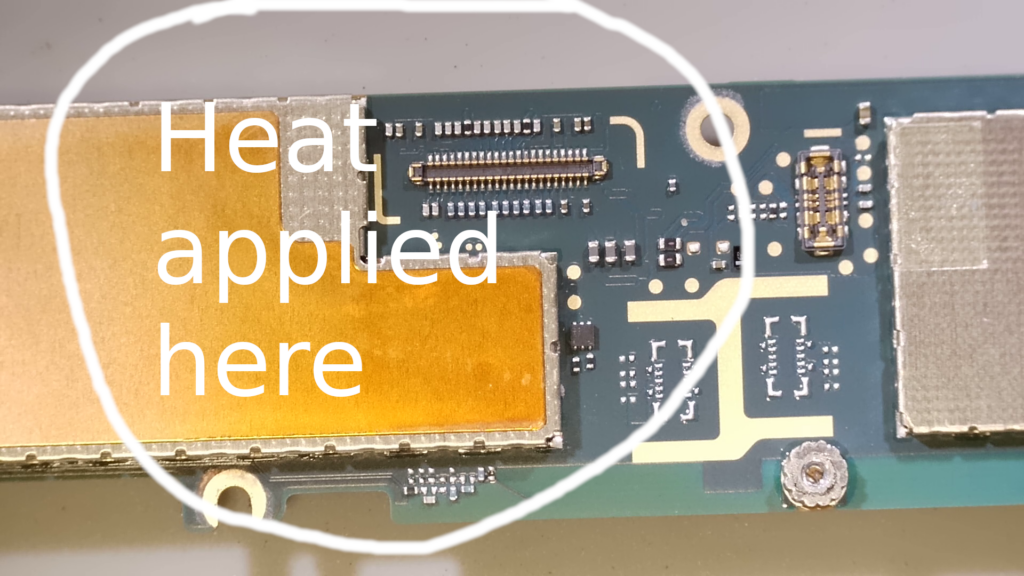

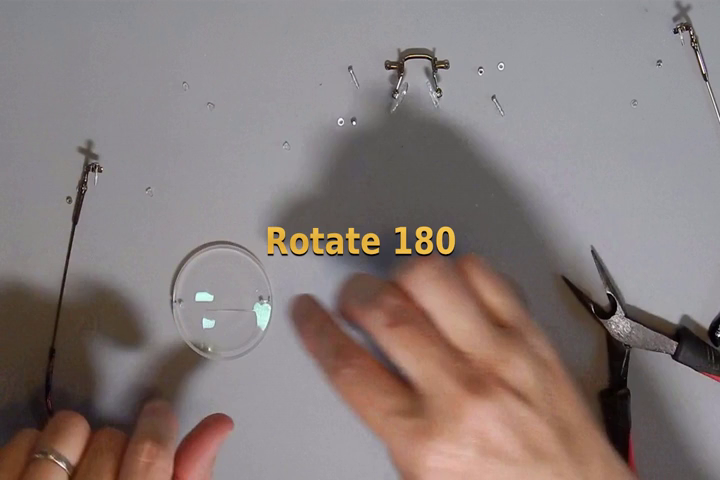

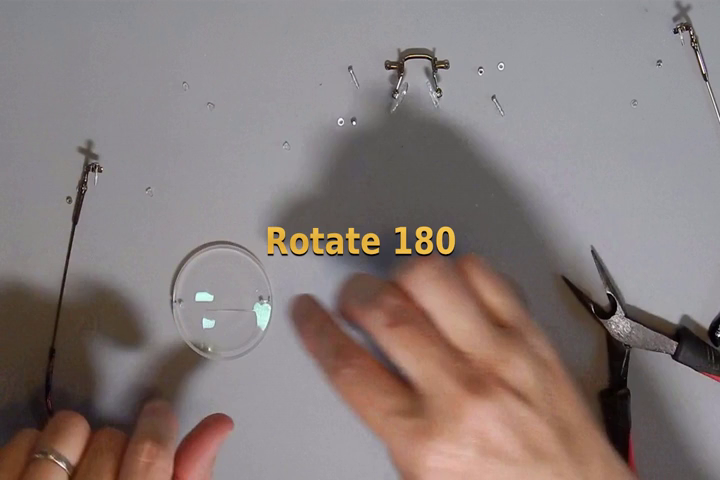

To move the magnifying areas from the bottom of the glasses to the top, you need to rotate the lenses 180 degrees, AND you need to swap the right and left lens. [So that the bifocal inserts are on the insides, and not moved to the outside of the lens…]

This means that when you ORDER the glasses you must REVERSE or SWAP the OS and OD (Left/Right eye) prescription lines! Other than swapping for left/right eye, the cylinder and axis numbers don’t need to be changed, as the 180 degree rotation is a perfect no-operation for them!

You also need to order a lens and frame style that is perfectly symmetrical, so that you can fit the lenses back into the frames after you rotate and swap them. I recommend metal frames held together with screws, or rimless models where the lenses bolt directly to the frame pieces. (But watch the mounting holes for symmetry!) Round lenses are usually your best bet, but you could make it work with some of the hex or octagonal lens styles.

I used Rimless Glasses 3229415 from Zenni Optical. If you use my $5 “Refer a friend” link, you get $5 off, and I get $5 towards my next non-standard experimentation with optics (because this wasn’t my first order from Zenni…)

5$ off link: https://bit.ly/3LLPZCX

Alternatively, if you don’t want to hack your glasses, I recommend the headband based magnifier with light in this amazon affiliate link:

https://amzn.to/3xTWRIV

Total cost? This set of glasses only cost me $54 (now that I know what I’m doing) but I did waste another $50 for a different set of bifocals before realizing that the standard bifocal inset area was too low for my needs, and that I’d have to modify the prescription by swapping the left/right eye so that I could rotate and swap the lenses.

Here is a video about the procedure: