We have owned an electric S-10 pickup truck for the last 1008 days (2.75 years) and used it as a daily driver. It was driven most frequently to the MARTA station, a 4 mile round trip commute, but also made trips to hardware stores, the Georgia Tech Campus, and to the homes of various people who were selling furniture or other larger items on craigslist. It uses twenty (six volt lead acid) golf cart batteries for its traction pack, and they have gradually lost capacity. When brand new, I would take the truck on 20 to 25 mile trips without stressing the battery pack. Recently however, the absolute maximum range of the truck had dropped to 12-14 miles and if you actually drove it 14 miles you could watch individual batteries hitting their absolute end of their state of charge. Although it could have functioned as a “Get to the MARTA station” vehicle for another year (or two?) I decided it was time to replace the pack to be able to comfortably go to the hardware store or make an extra emergency trip without worry. I have placed 685 charge cycles on the pack, which is in line with the lifespan for lead acid golf cart batteries.

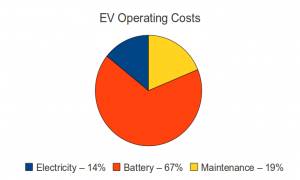

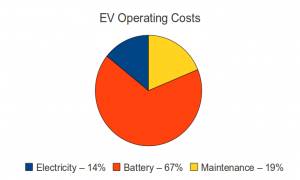

The replacement pack cost $2,171 (I gave back all but one of the used batteries for the core charge), which gives me the final piece of information needed to calculate the total cost of ownership over the last 1008 days. We spent $464 on electricity (estimated at $0.11 a KWH), $610 on maintenance, and the previously mentioned $2,171 on batteries. Obviously, the battery pack is the large cost here. In fact, the electricity cost is very small on a monthly basis, and was never more than 10-15% of our total KWH usage.

We drove a total of 4,861 miles in that timeframe, giving a cost of $0.66 a mile or $3.22 a day. This does not take into account licensing and insurance, but those costs would be exactly the same for an internal combustion engine (ICE) vehicle. If the S-10 were an ICE model, it would probably get around 20 mpg, so the fuel cost (estimating $3.50 for a gallon of gas) would be $0.175 per mile. So for 4,861 miles it would take 242.55 gallons of gas or a fuel cost of $849. This would imply that an ICE vehcile would have to have a maintenance cost of $2400 to get the same per mile cost of ownership as my EV.

Although ICE vehicles are more expensive to maintain, unless something major on the engine exploded, it looks like my hypotheical ICE S10 pickup wins the straight up cost comparison. Of course, I never had to drive out of my way to stop at a gas station, and there is the matter of 242.5 gallons of gas I didn’t use. (the lead and plastic in my batteries goes back to the factory to make new batteries)

In the interest of full disclosure, my first pack of batteries was purchased at a Sam’s Club for $1,800, so my true cost per mile is closer to $0.59. (But I used the pack replacement cost as an estimate for the cost of ownership for my next pack.)

I am hopefull that my 2nd pack (from Interstate batteries) will last longer, either because Interstate sells better batteries, or because I have learned how to care for them better. (Although I don’t think I did anything horrible to murder the first pack…)