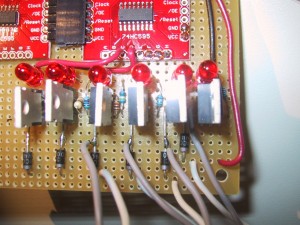

My BubbleDisplay project needed to control sixty DC motors or solenoids to control air injection into individual columns of liquid. Due to the large number of outputs needed, I am using a chain of (74HC595) serial shift registers so that three I/O pins can control all sixty outputs. As each serial shift register has 8 outputs, this requires eight chips (for a total of 64 outputs, four are unused). The 74HC595 can not source/sync enough current to drive the motors/solenoids directly, so I am using a TO-220 N-Channel MOSFET rated at 60 volts and 32 amps (digikey: FQP30N06L-ND) to drive the load, with an 1N4001 rectifier diode to handle current spikes. Because I had to make 8 (9 for a hot spare) copies of this circuit, I decided that fabricating a printed circuit board was the only way to go.

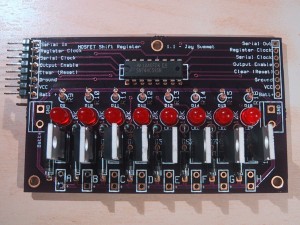

It only took me two tries (Moving from Version 1.0 to 1.1) before I was happy with the design, which you can see (populated for testing) above. Looks a lot nicer than the prototype, right?

Continue reading