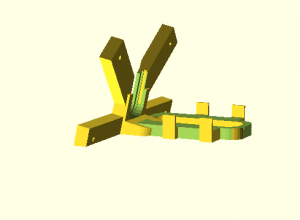

Nirav Patel has made a 3D model of a lens/projector/globe mounting system for a Microvision show-WX laser projector, a Opteka fisheye lens, and a frosted glass globe for a spherical display system first described here using OpenSCAD. The OpenSCAD file is here. I went through the trouble of installing OpenSCAD and exporting the file as an STL file so that I could print it. If you want to avoid that trouble, you can download it from me here: lens_mount.zip.

Category Archives: Projects

Dark wood table on a sewing machine base

Singer Sewing Machine Base gets a new table top

My wife purchased a few singer foot petal operated sewing machine bases and we finally finished one of them. The table top is made out of a piece of 18″ x 36″ wood purchased from Lowes that I edged with a piece of rope trim. After lots of sanding to get the edges of the trim and the wood to line up (the trim started off just slightly wider), my wife took over and stained and sealed the table top. After I screwed it to the base she had cleaned up and spray pained, here is the finished result.

Using refrigerator door bins and vegetable crisper drawers for garage organization

Cardboard boxes are fine, but refrigerator door bins and vegetable crisper drawers are nicer for storing things. The good ones I used here are made from clear plastic so you can see inside them easily and they don’t block light.

Of course, they are terribly expensive to purchase for this use, but with the (lack of) quality of Kenmore /Amana refrigerators manufactured after 2004 you can find free donor components relatively frequently. I also believe that with the addition of standard closet shelving support brackets the glass shelves from these fridges can be re-purposed into standard wall shelves.

Boost Converter Schematic

I have drawn up a schematic (click to enlarge) of the high current and sensing portions of my maximum power point tracking (MPPT) 2-phase boost converter battery charger circuit. The schematic does not include the micro-controller, MOSFET gate driver IC, and associated power supplies, as those items are on the (relatively) low-power side of things.

What do all of these things do?

- L1, Q1, and D1 – These three components make up the heart of the boost converter. When Q1 turns on, power builds up in L1 as the current rises. When Q1 turns off, all of that power exits via the only available route (out past D1) and the voltage is boosted as the inductor (L1) resists the current change. If you turn Q1 on and off very quickly (under control of the micro-controllers’ PWM output via a MOSFET gate driver) it raises the output voltage higher than the input voltage.

The $25 Sous-Vide Egg cooker

I put together a $25 sous-vide egg cooker with a $20 PID temperature control module I purchased from ebay (which included a thermocouple and free shipping), a $2 immersion heater and a $1 extension cord (both purchased at a thrift store). I added a few crimp on connectors that I already had (but we’ll say you could get a few for $2 at the hardware store) and a free bowl and clothespin that I stole from the kitchen.

I’m happy to report that it cooked the egg just fine.

I’m not 100% certain I’m going to get into Sous-Vide cooking, but the technology has several alternative uses: unpasteurized milk heating for making cheese, automatic baby bottle warmer, etc…

A few downsides to my $25 setup:

- The temperature of the water in the bowl would vary by about 5 degrees from the top to the bottom as I did not have any type of pump to circulate the water. I was hoping that convection currents would do something for me, but apparently the water just stratified.

- It has a few exposed wires laying about, and a bowl of water sitting near them. For permanent use an enclosure will add to the overall cost.

- It can only cook a single egg at a time. The immersion heater draws 125 watts at 120 volts (around one amp) which can easily be switched by the internal relay in the PID controller (rated up to 3 Amps). But, it won’t work with anything big (like the electric kettle I also purchased at the thrift store) until I add a bigger 10-25 amp relay (solid state or otherwise). If you plan on running a big 8-12 amp load from your PID module, I suggest getting one that has a 12 volt output designed to directly control a solid state relay.

Adventures with a boost converter

A boost converter is a dynamic electronic circuit that can “boost” a lower voltage up to a higher voltage. Current is of course reduced in the process, but if you design it right you only lose 5-25% of the overall power. I am in the process of building one that will convert the approximately 70 volt nominal output provided by my solar panels into 125-140 volts that will charge my trucks batteries. I also plan on adding a bit of maximum power point tracking and battery charge regulation to the control logic, making it a MPPT solar boost converting charge controller. Why do I have all of these wires and parts scattered across the dining room table? Because the market does not sell what I need. (Believe me, I’ve looked.) So I have decided to build what I need.

Not being an electrical engineer, I probably won’t be able to get 95% efficiency out of my system, but so far I’ve measured 85-90% efficiency when doubling voltage. [Test 1: 23 volts in at 0.28A for 6.44 watts, 46 volts out at 0.12A for 5.52 watts means 0.92 watts loss = 0.92/6.44 = 0.142 or 14.2% losses. Test 2: 34.8 volts in at 0.35A for 12.18 watts, 72.3 volts out at 0.15A for 10.84 watts, or -1.335 watts loss, which is 10.9% losses.]

I’m still running things off of a (relatively) low voltage and current supply (two/three 12V 5AH batteries) while getting everything working, and only boosting up to 50-72 volts when testing.

I had the circuit up to 95 volts (max of 16 watts) on the output side, but I really want to optimize it for a voltage doubling, and you lose a good amount of efficiency when going higher than a 50% duty cycle.

I have also not been able to find a commercially available boost regulating control IC that works with 100 volt inputs and produces up to 200 volt outputs. One probably exists, but digikey doesn’t appear to have it. I’m solving this problem by programming my own using a PIC micro-controller. At least the programmable nature of my controller should also allow me to add the battery charging maximum voltage/current and solar panel MPPT logic into the system. I am currently working on a single phase boost converter, but the plan is for the final system to be two phase (which basically means that I use two of them in parallel). This means that I need my single phase system to be able to support 100-175 watts maximum. Soon I’ll be moving from my 25 watt resistive load (25 watt lightbulb) to a 100 watt resistive load. Eventually, I may even borrow a 75 volt power supply and test it up to 140 volts.

While working on my boost controller, I’ve found the following reference links very useful:

- http://www.ladyada.net/library/diyboostcalc.html

- http://www.nerdkits.com/videos/backlight/

- http://www.daycounter.com/Calculators/Switching-Converter-Calculator.phtml

- http://www.arrickrobotics.com/highload.html

I have also made a few mistakes that people making their own boost converter may want to avoid:

- Within reason, the higher the switching frequency the better. I started off using a PIC12F683 chip which only has a single PWM output. Because I was planning on building a two phase system, I decided to code my own PWM loop that would support two phases with a 180 degrees difference. (A fancy way of saying that they would each be ON for the same amount of time, but that while channel A’s ON time would start at the beginning of the period, channel B’s on time would END at the end of the period. If the duty cycle went above 50% they would overlap for a bit in the middle.) After spending an hour on my fancy 2 phase PWM system and testing it with some visible LED’s, I took all of the delays out of it only to find that my 8Mhz internal oscillator could only support a period of 1.5-3 kHz. Sure, it sort of worked, but you could HEAR it switch. It also required a much larger inductor for the same power. So, I switched over to using the built in PWM subsystem, which can easily hit 73 kHz while still having 5-6 bits of precision. I now plan on switching over to a PIC 16F chip which has a dual channel PWM that I THINK can do an 180 degree 2 phase signal in hardware (if I’m reading the specs correctly…)

- Most MOSFETs require at least a 10 volt gate signal. If you switch them with a 5volt logic signal directly from the PIC they will switch (at least mine did), but they will not carry current without burning a lot of it up as heat. I was wasting 80% of my power as heat in the MOSFET until I wired up a transistor off of a 12V rail to amplify the signal to 12 volts. I plan on using a IXDN604PI gate driver chip for my final design.

Using the Microchip PIC Kit 1 with Linux

The PICKit 1 is a combination programmer and development board for midrange PIC micro-controllers. In addition to being able to program FLASH pic devices, it also allows them to run and access 8 (charlieplexed) LED’s, a pushbutton switch, and a potentiometer. It’s a great little board for learning the basic of micrcontroller programing, but unfortunately it is not supported by Microchip’s new MPLAB X software (that is written in Java, and supports Linux/Mac in addition to Windows).

You CAN however use the PICKit 1 under linux. The piclab software is supposed to support it (I have not tested this). I use version 1.6 of the PicKit1 flash usb programmer for unix. Even the newest 1.6 version reports checksum errors after writing the hex file, but it does work correctly.

To make it work as an external program in MPLABX I had to select the “format HEX file for download” option under the Linker so that it would not fill all 2048 flash bytes when the program was smaller than that. I am able to manually run the usb_pickit command after building to flash the code, but it’s kind of annoying, as that program has a problem verifying the checksum and reports an error every time (which is interpreted as a build failure) plus, I have to run mplab X with root permissions to be able to access my USB port.

Ferrofluid Sculpture test 3 (a)

The main problem I had with my previous ferrofluid test was that the magnets would repel each other enough that I was not able to achieve a single, solid object. After (mostly) cleaning the ferrofluid off of my magnets, I carefully removed half of the magnets and a washer, replacing them with a bit of Sculpey that weighted exactly the same. I pushed half of the magnets into the Sculpey, and then used them to hold another 17 magnets “outside” of the main body. This spacing keeps them far enough apart that they do not repel each other, and the Sculpey fills in the areas between the magnets.

The Sculpey will probably lose some weight when it is baked, but I’m counting on the ferrofluid to allow me to adjust the weight of the hanging object suitably. I don’t want to test it with ferrofluid until after I bake the Sculpey and coat it with black spray paint. The punk potato has a magnet with a plastic cap on it, so I needed to determine the lowest possible temperature that will harden the Sculpey without demagnetizing the magnet or melting the plastic cap. (Currently, the “punk potato” is right at the lower weight limit for successful levitation.) As the lowest curie temperature I could find for common rare-earth magnets was 310 °C, the plastic (which I assume is ABS, with a melting point of 105 °C, (or 220 °F) is my limiting factor. I set the oven to 215 °F and wrapped some tinfoil around the plastic in an attempt to protect it.

When I showed it to my wife she closed one eye, tilted her head, and said “Weird”, so I know I’m getting close to the aesthetic I’m aiming for.

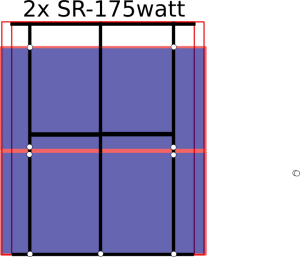

Solar Panels on the Electric Truck

I purchased two used GE Energy GEPVc-175 watt solar panels and mounted them to the bedcover of my truck using 10-24 machine screws and T cone washers as rubber vibration dampers. Each panel weighs 31 pounds, and is rated to deliver up to 175 watts of power in full sun (at around 36 volts each, or 73.4 volts at 4.7 Amps in series). I am still waiting on a group of Georgia Tech ECE students for the magic box that does maximum power point tracking (MPPT) and voltage boosting to charge my 120 volt battery pack, but I hope to be generating 1-3 miles of my daily commute from the sun soon. As my daily commute is 4 miles, this can be a significant percentage of my total energy usage.

I have calculated that in the summer the panels are far enough behind the cab that they will not be shadowed by it, even if I have to park facing south. In the winter and early spring / late autumn I need to park facing north to avoid shading a strip of the solar panels.

I still need to figure out a way to tilt the panels towards the sun to collect as much energy as possible. This is especially critical during winter, when the solar angle is way off of vertical. As the bed cover tilts, AND the bed of the truck can tilt (the other way) I figure I can work something out (with a few pieces of wood cut to the correct height, or linear actuators if I want to get fancy.