Now that it is summer, and outside temperatures are reaching 26-35 C (80-95 F), my dual TSM2500 (Rebranded CH4100) chargers are overheating. After about an hour charging at full power, they reach around 74 C (165 F) and shut down. The ThunderStruck Motors EVCC records this as a “normal” end charging event (because the Amperage output goes to zero), and for some reason it triggers a ground fault on my EVSE (perhaps they have a thermal switch that shorts the charger to ground to shut it down, or maybe my JuiceBox Pro 40 is just overly sensitive?)

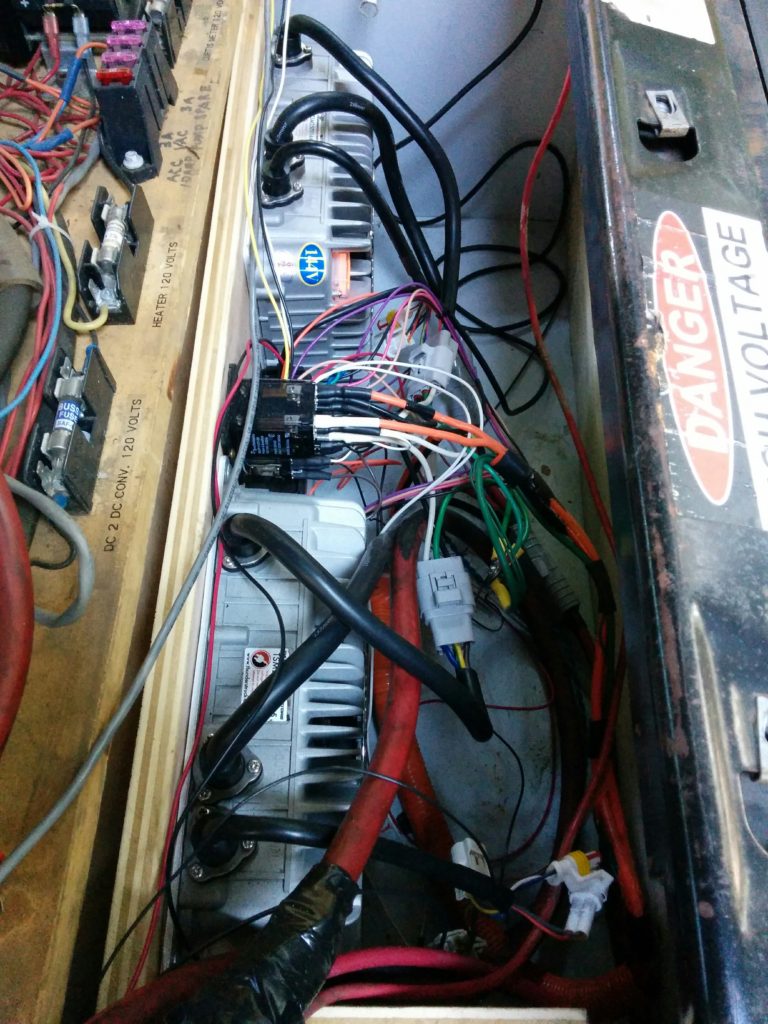

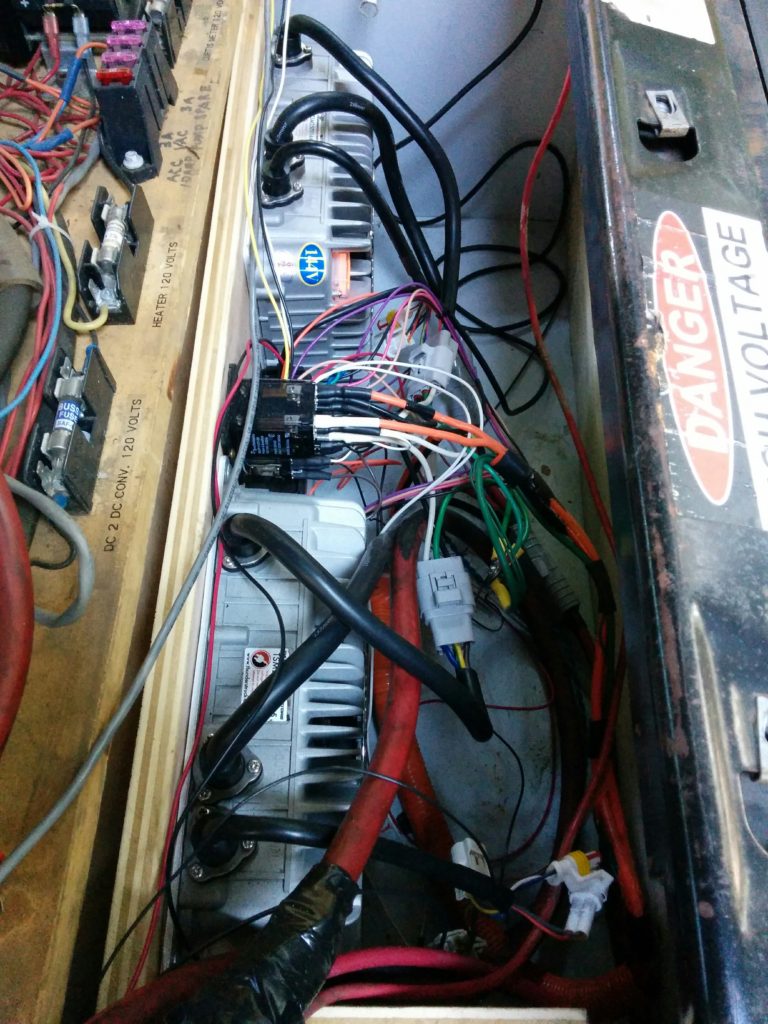

I guess the overheating is to be expected, as the chargers are in a five sided box (with only the top open) and mounted to a piece of (thermally insulating) plywood. Although there is a tangle of wires in front of them, the wires really don’t interfere with the airflow as much as it looks like from this top view.

In my defense, the charger’s manual (v. 1.05) specified that I should leave a 50mm (2in) gap in front of the charger for proper ventilation and I left around 8 inches. It also noted that the “Working temperature” for the chargers was -25 to 55 C (-13 to 131 F). It didn’t mention anything about thermally bonding the charger to a heatsync.

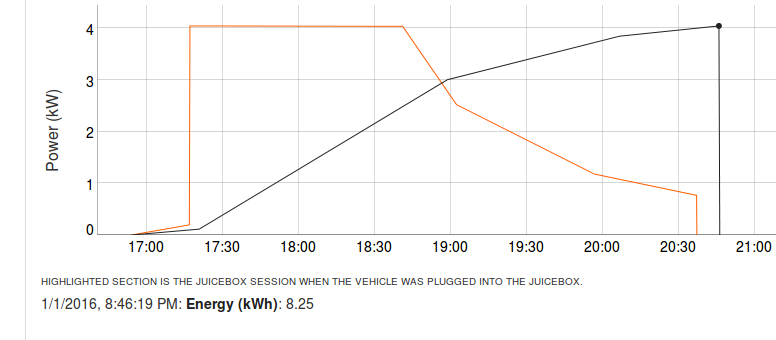

As a temporary solution, I have re-configured my 80% charging profile to only run at 1.2 kW (8 amps total, or 4 amps per charger on a 128-131 volt pack). This is about 25% of the 15 amp max power that the chargers are capable of in cold weather. At this relatively low power, each charger is outputting just over 500 watts, and even in 32 C (90 F) weather the charger temperature hold steady at 50 C (122 F).

Charging at one kW may not sound terribly fast (it’s not), but this workaround is actually fine for 95% of my charging needs, as I rarely need to refill more than 8-10 kWh (20-30 miles) per day of use, and L1 charging overnight works fine for most of my needs.

However, I purchased the dual charger setup so that if I was necessity charging away from home I could charge at a 4 kW rate, so I want to make improvements to my cooling so that I can run the chargers at full power (without them overheating after an hour) if needed.

ThunderStruck Motors suggested that I mount the chargers to an aluminum heatsync, which is a good idea, but difficult and costly to implement.

I have decided my first order of business is to drill two 4″ air intake holes into the bottom of my charging enclosure and duct them to the top of the chargers right over the fan using dryer hose. This will allow the fans to draw cool(er) outside air directly over the vanes on the charger, and keep the heated exhaust air from mixing with the cool(er) incoming air. Since the top of the box is open, the heated output air should have no problems escaping, as convection will assist the fans in exhausting the hot air upwards. If adding intake air vents doesn’t solve my problem, then I’ll worry about making an alunimum heatsync plate to take the place of the plywood.