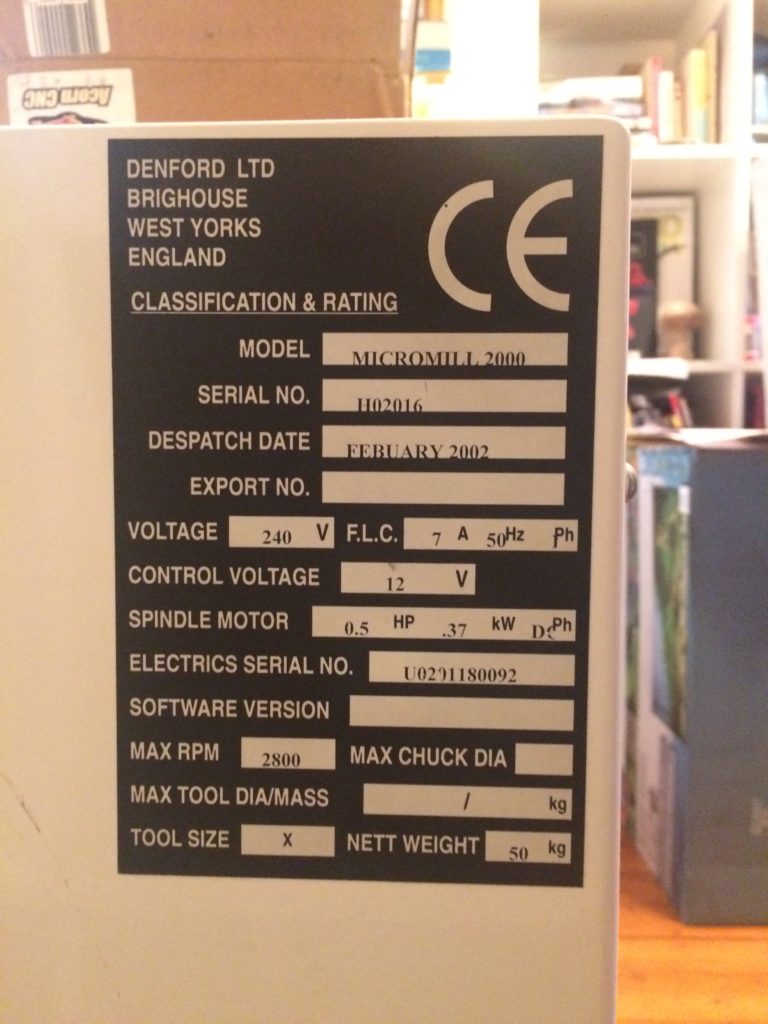

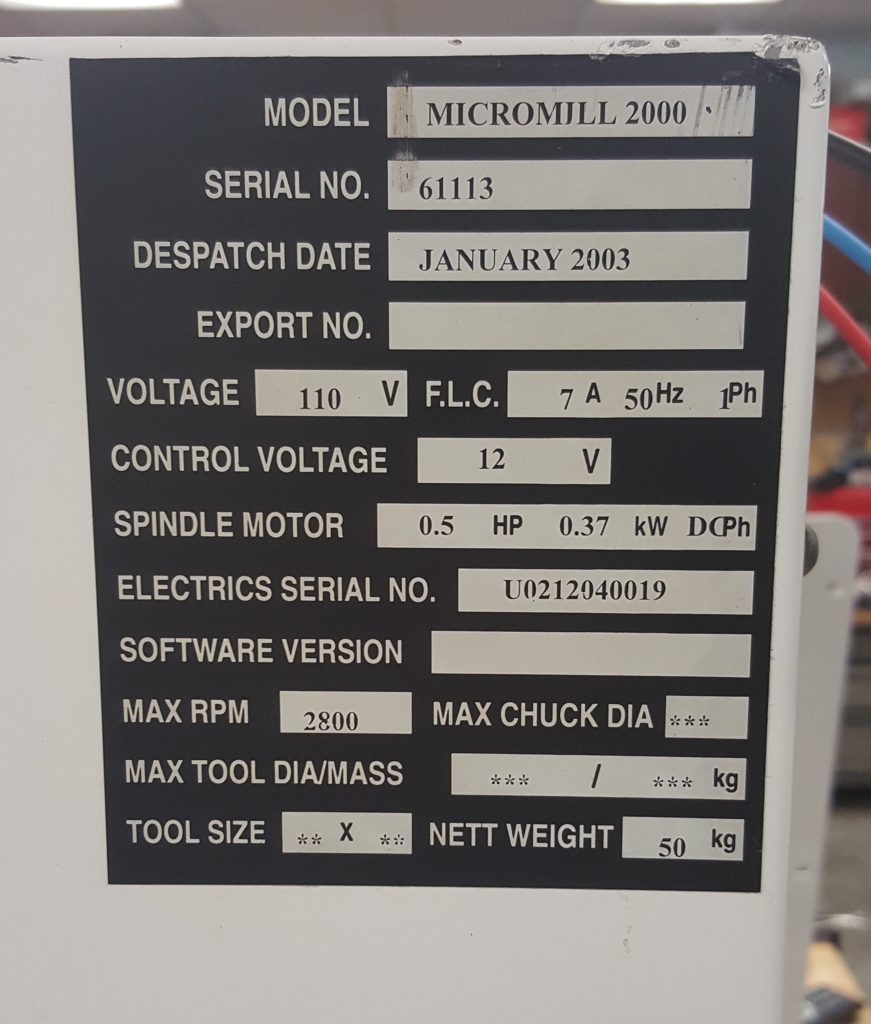

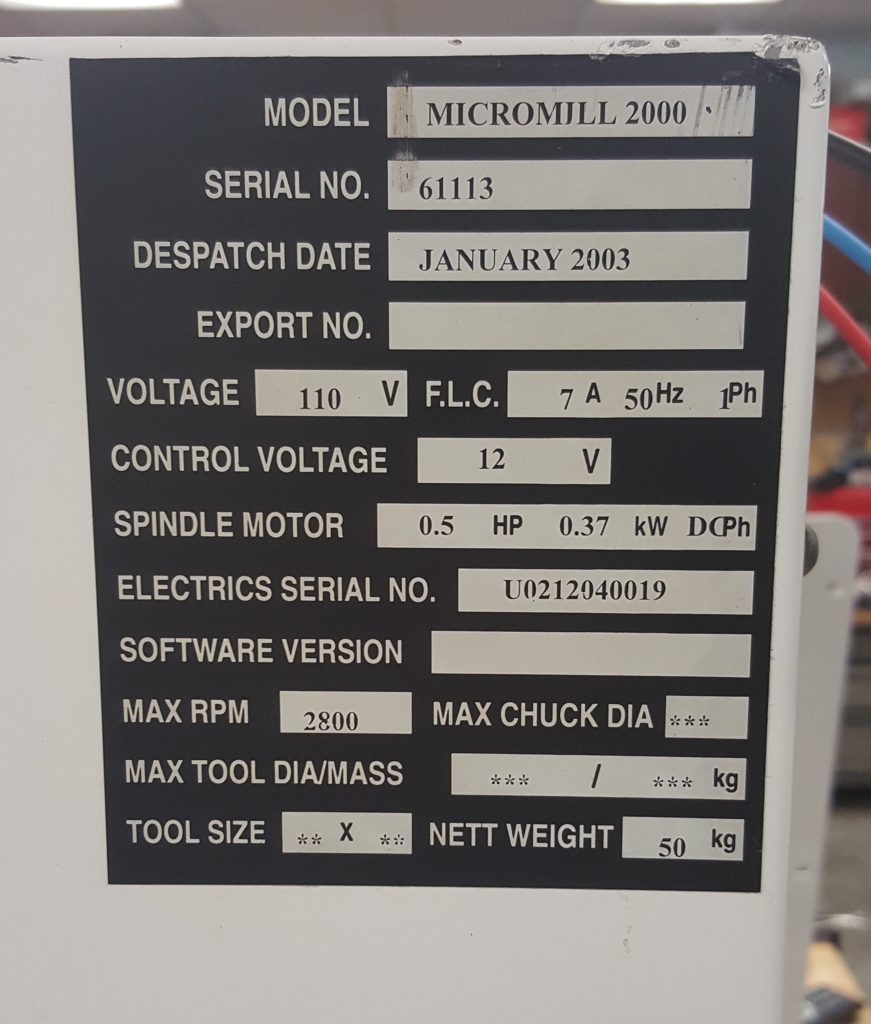

Cliff Burger is part of a makerspace ( http://www.tcmakerspace.com ) which had a Denford Micromill 2000 (January 2003 dispatch date) donated to them. When referring to my four part series( 1, 2, 3, 4) about how I got mine working under CNC control, they noticed a few differences with their model and wanted to share that information.

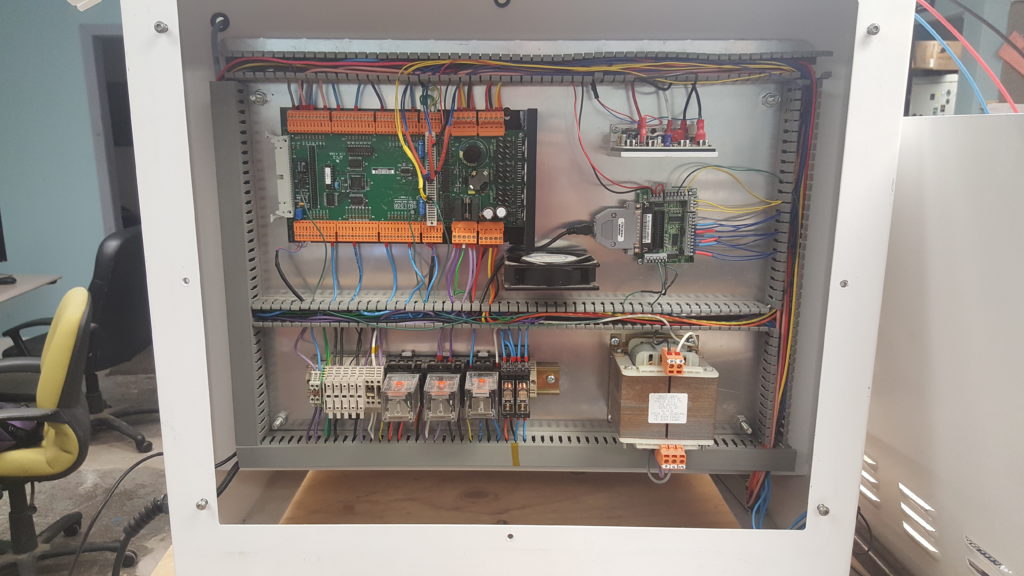

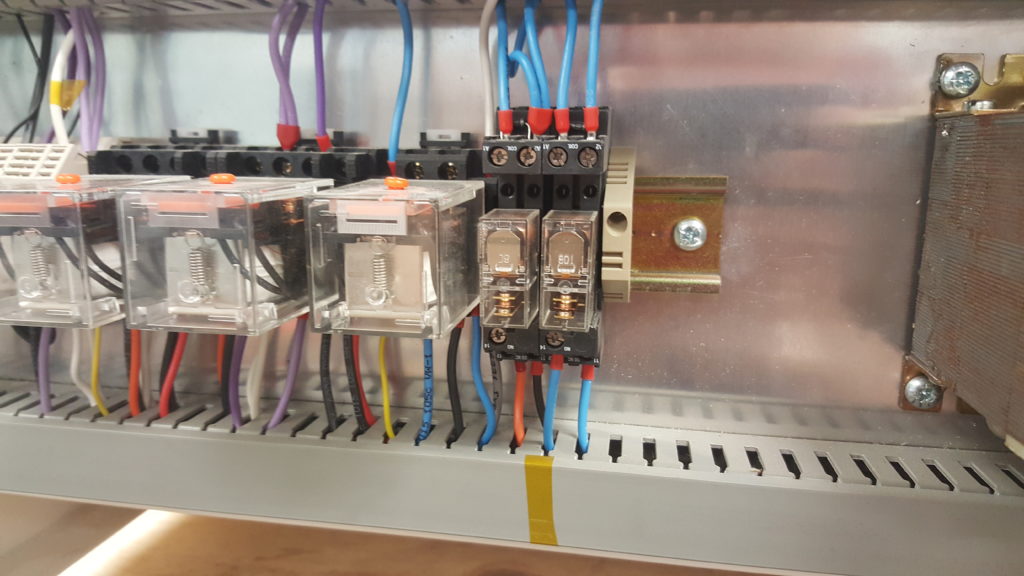

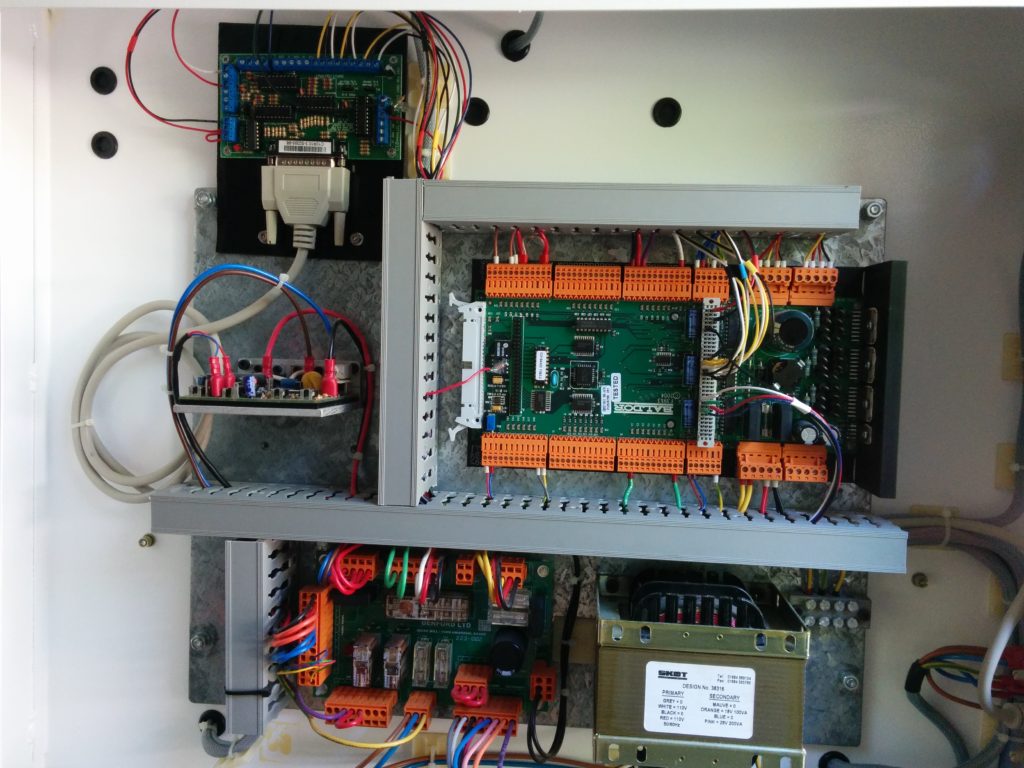

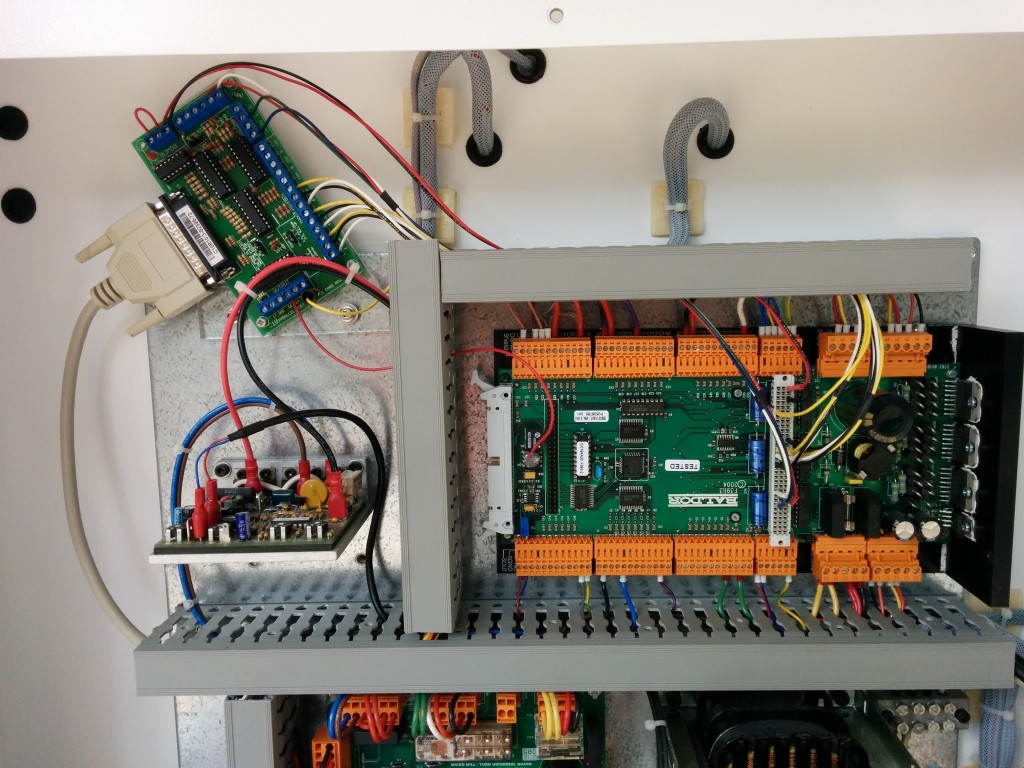

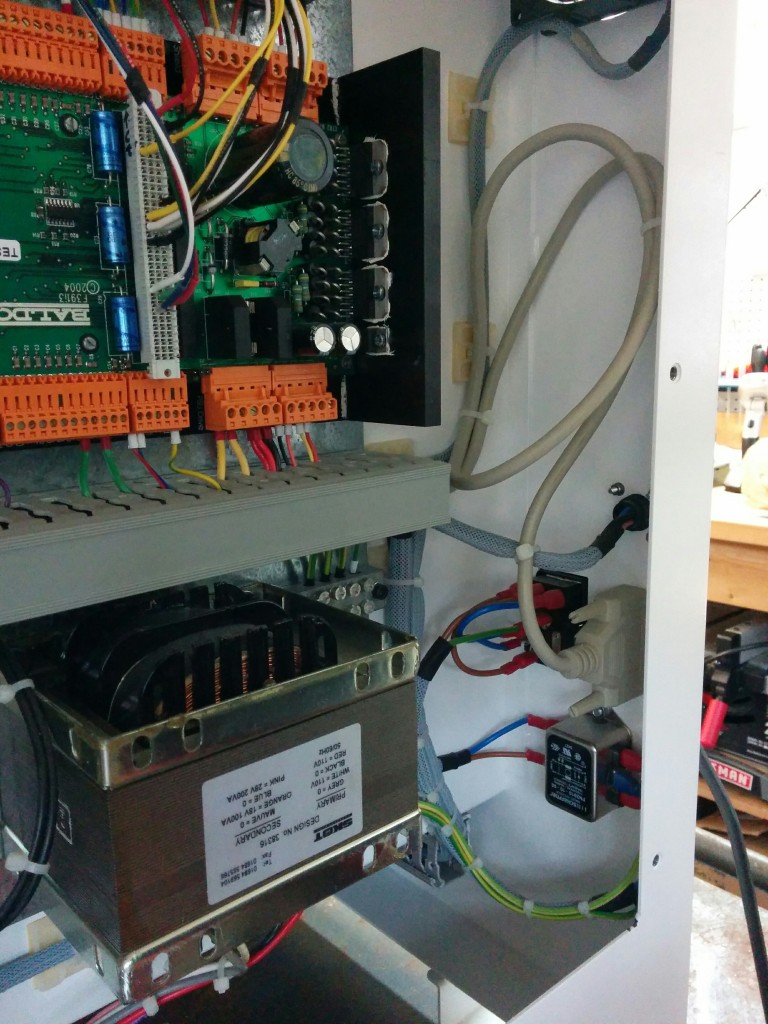

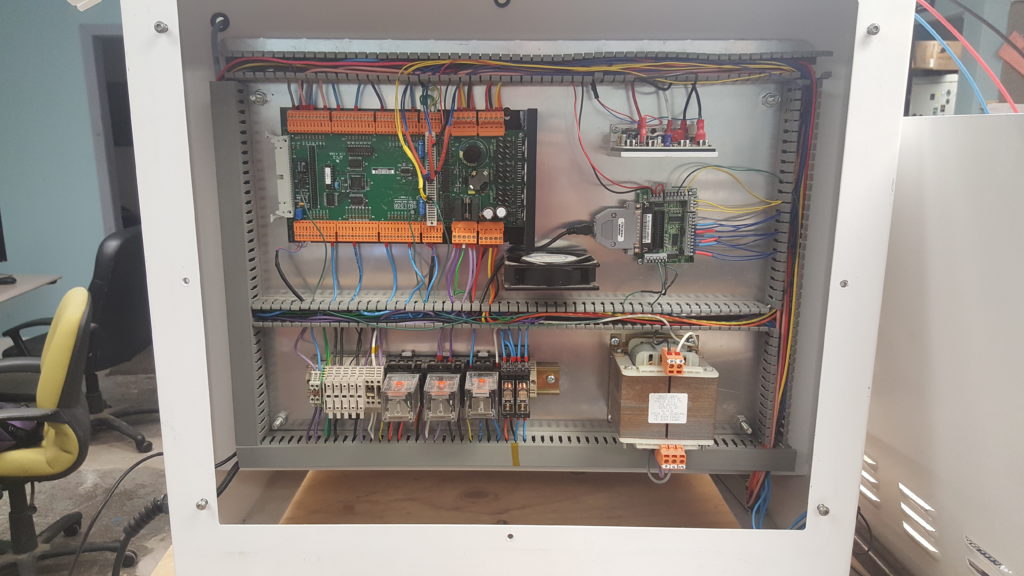

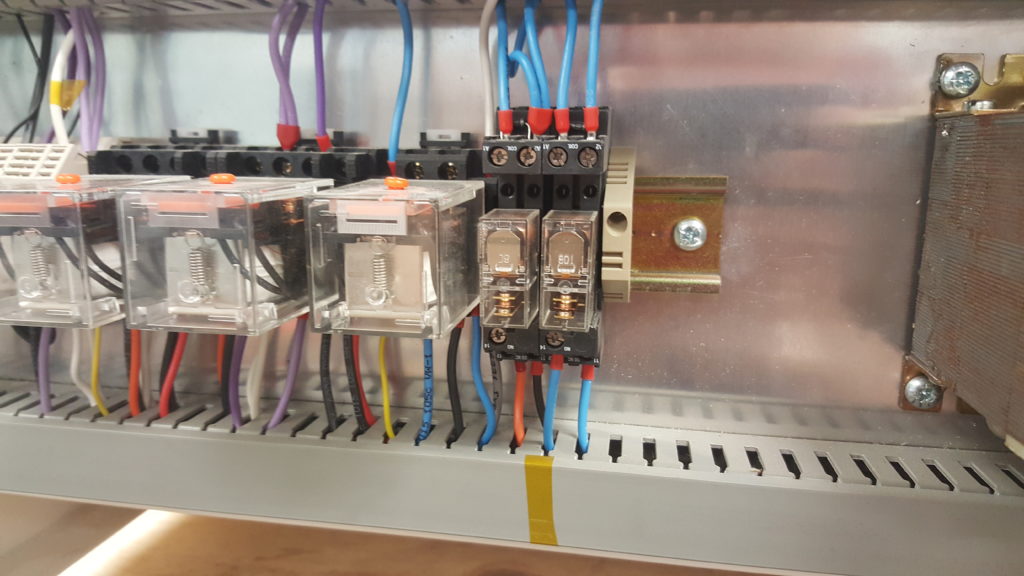

Instead of having a custom made relay & power board, their mill has it’s relays mounted to a DIN rail (bottom left of the case in the image below). The spindle go relay (SGR) is located in the 2nd from the right position.

A quote from Cliff:

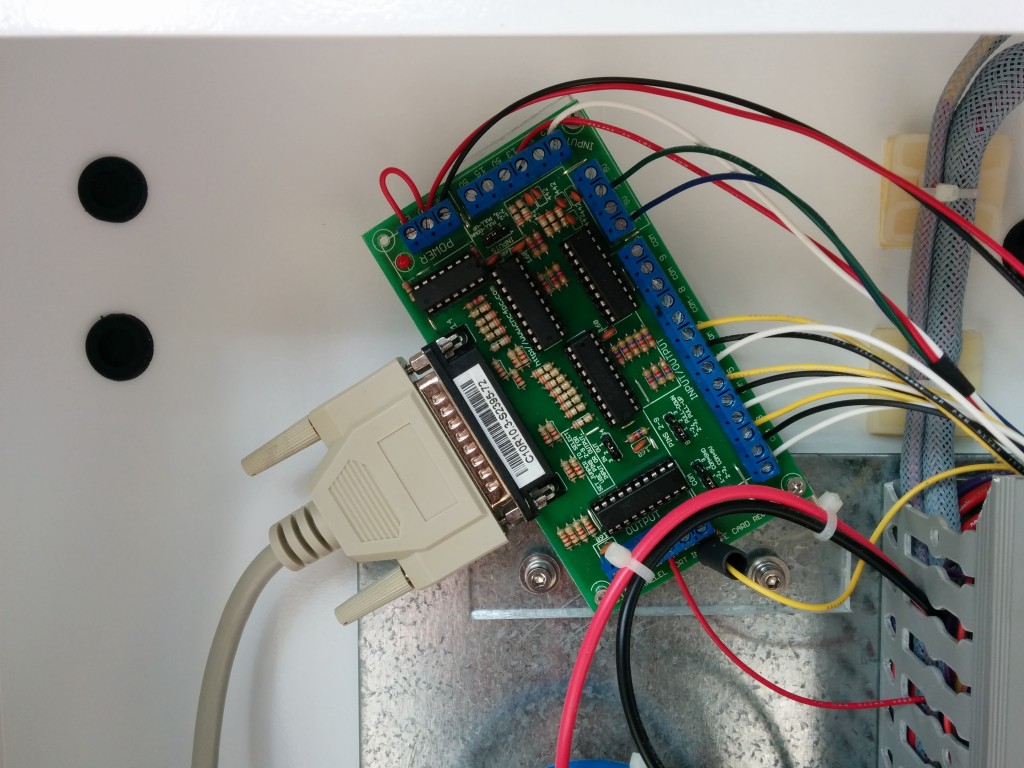

On the DIN rail, the spindle activation relay is the second one in from the right. It’s a 12v relay with the ground for the coil being controlled by the C6 pin. However, currently the relay never sees a 12V signal either. Not sure if it’s something wrong with my board or it’s waiting for another command signal before it sends the 12V out as well. Either way, I’ll likely just get a 5V relay and switch it right off the BOB, but for the time being I’ve moved the orange wire from the “14” position to the “12” position to supply power to the board at all times.

Cliff also sent along his mach3 config file, which you can download here (note, you will have to remove the .txt extension from the file to use it.) Denford.xml.txt

He has the following caveats:

Things to note about the mach3 config:

1) My limit switch are on different pin numbers due to me chopping 1 wire a bit shorter than I should have (oops!).

2) default units are in inches so the steps per INCH are correct, but may need slight tweaking for each application.

3) backlash settings will need to be measured for each mill, or disabled.

4) I’m running a UC100 UBS adapter board so Mach3 may give an error message the first time you open it with this config file.