I received the new and improved serial stepper controller board (version 4) from Ocean Controls. (Cost: 65 AUD) Although it supports up to a 6kHz stepping rate, I found that my steppers can only be driven at the RATE 12 setting, or approximately 745 steps a second. I’m not sure if this is because I’m not providing enough voltage or power (currently at 6v and 1.66A) or if that’s just the maximum rate of the steppers. When I try to use RATE 11, the steppers make nasty noises and are obviously loosing steps here and there. I don’t think it’s a current issue, as the usable RATE doesn’t change when running one stepper or two steppers at the same time. At some point in the future I’ll find a higher voltage power supply and see if that allows the motors to step faster.

This speed is still a small improvement over the original stepper controller, which worked at 605 steps a second maximum speed (despite the fact that it was supposed to run at 1000 s.p.s. or 1kHz). The documentation for the SSCB says that rate 12 is equivalent to 755.9 steps/second, so my measured 745 is relatively close, and probably is due to the built in acceleration and deceleration at the start and end of motion.

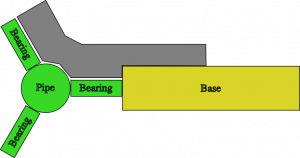

The real benefits of the version 4 board is the ability to start multiple motors at the same time, and get a prompt back over the serial line when the motors stop moving so I don’t have to poll the position (which still results in the controller board dropping steps). The new board also includes two command controlled relays, which will be perfect for turning on a spindle motor via program control, and perhaps enabling the stepper motor power supply.

The new multi-motor start command and feedback when finished greatly simplified the python code to interface with the stepper controller, and the serial control board no longer drops characters (perhaps because I am sending less characters and waiting patiently for motors to finish moving.)