My electric bicycle has a motor that draws up to 450 watts (if I drive it over its nominal 250 watt rating), and the batteries have only 5AH (approx 120 watt hours) total capacity. Keeping in mind that I should only discharge the lead acid batteries to 50% (approx 60 watt hours) this indicates that I can only use the motor at full blast for eight minutes.

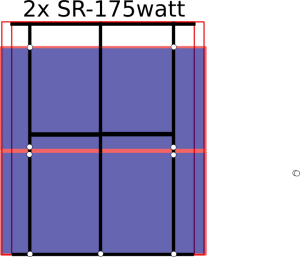

But, since I only use the motor to help go up hills and provide extra acceleration, and most of the time it is not drawing the full 450 watts, I actually have a much longer run-time. I deliberately chose to put small batteries on the bike both to keep the weight down, and to allow them to be recharged using solar cells (8 watts) in a reasonable amount of time. Under full sun, hypothetically the solar cells will generate 60 watts of power to recharge the batteries from 50% to 100% charge in 7.5 hours. In actual practice, it takes more like 10 hours of sunlight, usually around two days.

How does this work in actual practice? Here are some examples.

Early Saturday morning I biked a 2.8 mile round trip to the post office, using the motor lightly. I left the bike outside all day and it was recharged by 4pm. On Sunday afternoon I rode the bike to a friends house ( a 2.5 mile round trip). Because it was overcast and raining, no charging occurred before I then rode the bike another 0.9 miles to the Marta station (up hill) and left it all day. (At this point the batteries had been used for 3.4 miles of travel without charging.) When I returned at the end of the day and rode the bike home (another 0.9 miles) it was not fully charged (due to the ride home) but the voltage had gone up significantly. After leaving it out in the sun for another day the batteries were fully charged.

In general usage, I typically only use the bike two or three days a week (rain, schedules matching up, etc) so the two day charging time fulfills my needs. If the bike was my only means of transportation, I’d probably have to supplement the solar charging with a grid tied charger, or install much larger solar panels at a fixed location to charge the bike.